Mud Pump Accessories Inlet Pipe Pressure Gauge for Oilfield Drilling Rig

Basic Info

| Model NO. | Inlet Pipe |

| Standard | API |

| Model Number | F/Pz/P/Nb Series |

| MOQ | 3 PCS |

| Transport Package | Packing in Wooden Box |

| Trademark | BEYOND |

| Origin | China |

| Production Capacity | 500/Month |

Product Description

Product Description

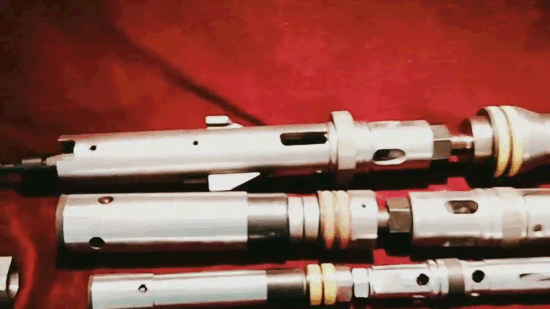

We supply mud pump spare parts like mud pump liner( including zirconia ceramic liner and high chrome bi-metal liner), mono-metal Liner, fluid end module, valve and seats, piston, piston rod, pony rod etc. parts for mud pump, we can also customize and machine as your drawing.

High chrome bi-metal liner:

Application:

High chrome bi-metal

liner is used as a kind of mud pump fluid end accessories in the oil drilling industry.

Features:

Our bi-metal liner, API certified, providing wear-resistant outer sleeve and high chrome corrosion-resistant inner sleeve. The high chrome liner has high rigidity of HRC>65 after heat treatment.

Advantages:

The bi-metal liner offers long service life of about 800 hours, which is 2 to 3 times the lifetime of common ones in severe environment.

Zirconia Ceramic liner

* Suitable for deeper oil reservoir,bad drilling geological structure environment,offshore oil and gas development.

*Service time is 5-10 times than bi-metal liners.The using time of liners are up to 6,000 hours.

*The material of ceramic liners is the increased flexible zirconium ceramic.These liners feature wear resistance,high anti-corrosion,high temperature resistance,high pressure,high intensity and high hardness.

*Reduced the freight cost,maintenance cost,labor cost and storage cost of oil drilling.

*Zirconium ceramic liners have better performance than alumina ceramic liners such as more toughness,longer service life,saving water lubrication,reducing wear of piston.

Difference between bi-metal liner and ceramic liner

Bimetal liner | Ceramic liner | |

Material | Outer surface: 45# forging steel Inner sleeve: high chrome alloy | Outer surface: 45# forgingsteel Inner sleeve: Zirconium ceramic |

Service cycle | Service life: up to 800 hours | up to 6,000 hours |

Price | $50---$250 | $600--$1100 |

We provide the following model and types liners and much more:

BOMCO | F-500 | F-800 | F-1000 | F-1300 | F-1600 | F-1600HL | F-1600L | F-2200HL |

Hong Hua | HHF-500 | HHF-800 | HHF-1300 | HHF-1600 | 3NB-1600F | 5NB-1600 | 5NB-2400 | |

EMSCO | F-500 | F-800 | F-1000 | F-1300 | F-1600 | FD-1000 | FC-2200 | FB-1300 |

Gardner Denver | PAH | P7 | P8/9 | P10/11 | PXL | PX-11 | PZL | PY-FXD |

National | 7-P-50 | 8-P-80 | 9-P-100 | 10-P-130 | 12-P-160 | 14-P-200 | 14-P-220 | N-1000/1300 |

Oilwell | A-850-PT | A-1100-PT | A-1400-PT | A-1700-PT | ||||

TSC | WF-500 | WF-800 | WF-1000 | WF-1300 | WF-1600 | WF-2000 | WF-2200 | |

IDECO | T-500 | T-800 | T-1000 | T-1300 | T-1600 |

1. who are we?

We are based in Shandong, China, start from 2016,sell to Eastern Europe(30.00%),North America(10.00%),South America(10.00%),Southeast Asia(10.00%),Africa(10.00%),Mid East(10.00%),Oceania(5.00%),Central America(5.00%),South Asia(5.00%),Domestic Market(5.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Drilling & Workover Rig,Water Drilling Rig,Pile Drilling Rig,Mud Pump,Drilling Rig Spares

4. why should you buy from us not from other suppliers?

1.Professional & Efficient, Customer Focus, Win-win Cooperation 2.Competitive price & within shortest lead time; 3. Overseas technical services

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Russian