Inner-String Cementing Equipment Guide and Casing Shoes

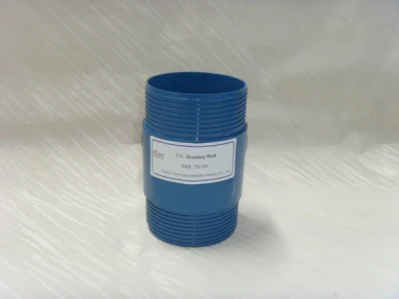

Conventional type Float Shoe//Float Collar 1. Sizes from 4-1/2" to 30" 2. Single/Double Valve 3. Thread:LTC,STC,BTC and

Basic Info

| Model NO. | ZSFS958 |

| Steel Grade | K55, J55, N80, P110 |

| Connection | Btc, Stc, Ltc |

| O.D | 270mm |

| Core Diameter | 102mm |

| Core Material | PDC Drillable |

| Height | 515mm |

| Transport Package | Cases with Pallet |

| Specification | 9 5/8" |

| Trademark | PYZS |

| Origin | Puyang |

| HS Code | 8481300000 |

| Production Capacity | 200 Units Per Month |

Product Description

Conventional type Float Shoe//Float Collar1. Sizes from 4-1/2" to 30"

2. Single/Double Valve

3. Thread:LTC,STC,BTC and Premium thread

4. PDC Drillable

5. Cement filled or Alloy Infilling

Float Shoe is made from seamless casing and the design ensures positive sealing in vertical, horizontal and deviated wells. It can be supplied in all grades of steel such as K-55, L-80, N-80, C-95, T-95, and P110. Traceability of component material starts from the mill material certificates. Float equipment are tested and rated in compliance with API RP 10F specs. It is equipped with a plunger valve which is fabricated of high polymer plastic or natural rubber. The valve is encased and held in place by the high-pressure cement mixture. Float Shoes can be manufactured in single /double valves and supplied with cement nose or aluminum noses.

Float collars are the same like float shoes except the lower end is pin thread. The usage of float collar is to make the casing landing easily by reducing the load and to make sure to prevent the drill fluid flowing into the casing. Internal parts are made of high quality materials to achieve high strength and PDC drillable.

Non-rotating Float Shoe//Float Collar

Non-rotating float equipment is installed a non-rotating plate on its bottom part, and it is operating together with anti-rotating cementing plugs. Non-rotating float shoe attaches to the end of the casing string. Non-rotating float collar is placed to one or two casing joints above float shoe and they are use to stop slurry from flowing back.

Stab-In Float Collar and Float Shoe

Stab-In Float Collar helps to guide the casing and put it into the hole. It can conform the drifting force of the packaging when it is laid in and guarantee the nature of the establishing. The stab in float collar is made by crimson oil tool and utilizes the spring driving back the pressure valve sort which is dependable. The lower end is the pin association which is joined with the packaging and the upper end is utilized for filling the bond, it has a sink foil opening which can dodge the turn. The Stab-In Float Collar provides the advantage of high strength design and pressure bump with back flow resistance, it has long periods of circulation with automatic fill-up that saves considerable running in time of the casing and provides easy drills out. The special non-rotating groove design ensures that cementing plugs are drilled out quickly.

Send to us