Geoalloy Drill Pipe/Round Drill Pipe/Smooth Drill Pipe

Basic Info

| Model NO. | Diameter 89mm*1500mm |

| Standard | API |

| Length | 1500mm |

| Usage | Oil Mining, Coal Mining, Well Drilling, Ore Mining |

| Material | Carbon Steel |

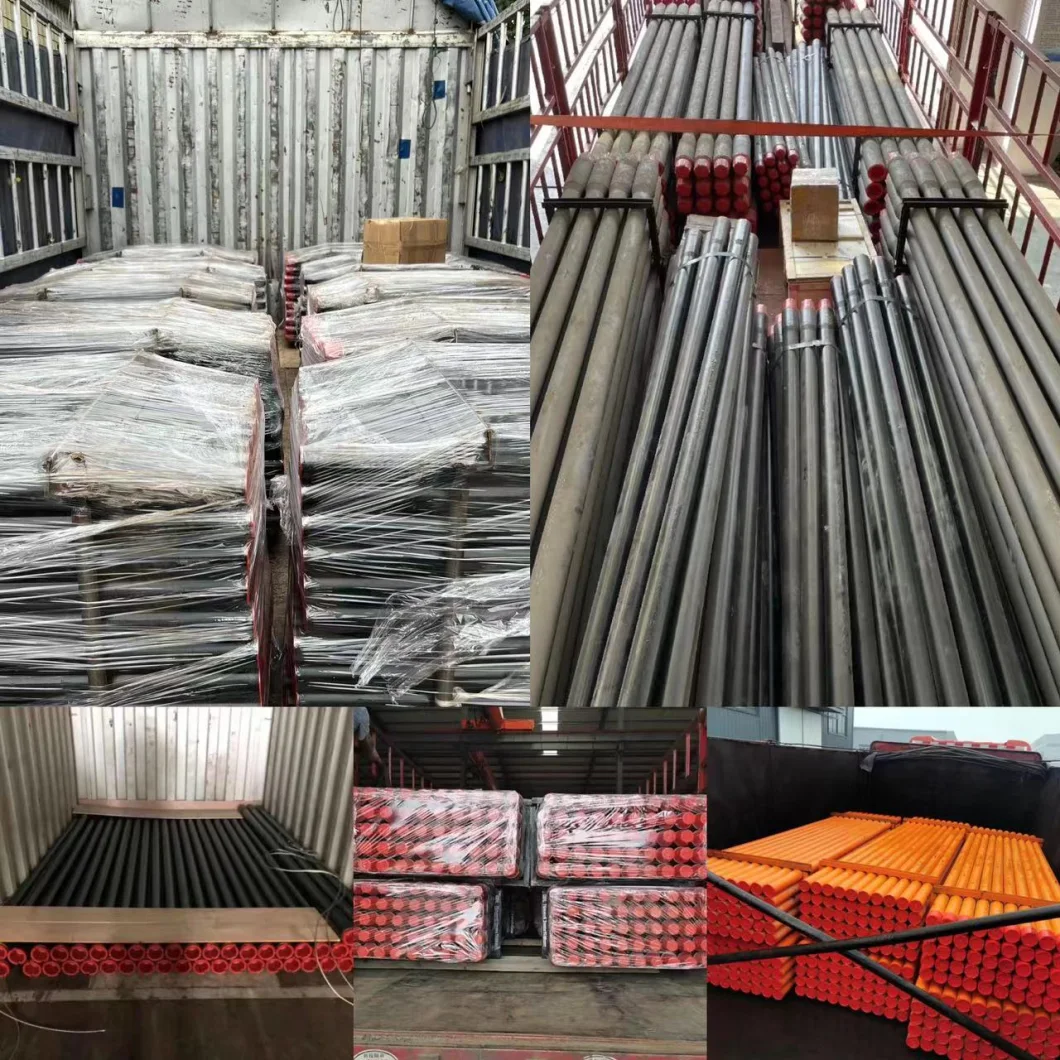

| Transport Package | Container Transport |

| Specification | Depends on the drill bit or rig size |

| Trademark | Huaxin drilling tools |

| Origin | Xingtai, Hebei, China, Borders The West |

| HS Code | 7304229000 |

| Production Capacity | 150000 |

Product Description

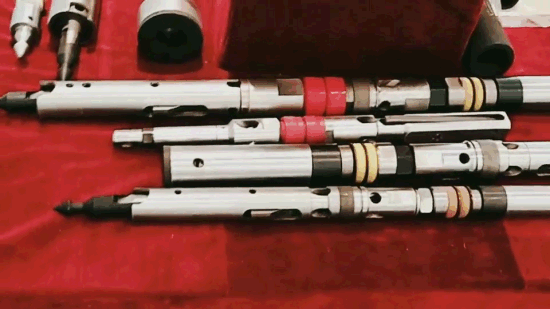

Geological drill pipe is used for coal mine water exploration, gas exploration and geological exploration drilling drilling tools. The geological drill pipes we produce include conventional drill pipes for coal mine tunnels, exploration pipes for oil drilling below Φ89mm and DTH drill pipes for mine drilling.

Connection form: flat buckle and taper buckle.

Flat buckle: Φ34.0mm, Φ42.0mm, Φ50.0mm(drill pipe diameter diameter).

Taper buckle: Φ63.5mm, Φ73.0mm, Φ89.0mm(drill pipe diameter diameter).

Flat buckles are generally used for small diameter geological drill pipes. As the diameter of the drill pipe increases, the drilling depth and the torque of the drill pipe will increase accordingly, and the drill pipe connected by the taper buckle can ensure the maximum transmission of torque when working on the drill pipe, and it is also more convenient when disassembling. It can also be customized according to the special needs of customers.

Application areas: drilling, mining, anchoring in coal mines, mines, construction, water conservancy engineering, railways, highways, bridges and tunnels and other industries. In coal mines, it is mainly used for coal mine water exploration, gas exploration, and roadway exploration.

Our company's product advantages: the main body of the drill pipe uses high-quality geological alloy steel pipe, the drill pipe joint uses high-quality alloy structural steel, through high-pressure molding, true air conditioning processing, friction welding, overall surface hardening for manufacturing, thread processing using advanced automated processing equipment, effectively guarantee the processing accuracy of each product, first friction welding after the thread processing production process, to ensure that the deep hole drilling when drilling multiple connections of the best coaxiality standards, compared with similar products, with high bending strength, large rotation torque, Smooth operation and other characteristics.

| serial number | Specifications and models | Connection method | ||

| Spiral diameter(mm) | Length(mm) | Wall thickness(mm) | ||

| 1 | Φ50mm | 500mm-3000mm | 8mm | Wire buckle connection |

| 2 | Φ63.5mm | 500mm-3000mm | 8mm | Wire buckle connection |

| 3 | Φ73mm | 500mm-3000mm | 8mm | Wire buckle connection |

| 4 | Φ89m | 500mm-3000mm | 8mm | Wire buckle connection |

Q: Are you a manufacturer or trading company?

A: We are a specialized manufacturer.

Q: What are your main products and what are their uses?

A: Our products are mainly used for drilling and surveying, and the products are drill pipe and drill bits. They are used for underground work in coal mines.

Q: What are the payment terms?

A: Our payment terms are 30% deposit in advance to start production, and the remaining payment is settled before leaving the factory

Q: We have customized models, do you need us to provide samples?

A: Yes, each specification size is more, or mainly samples.

Q: What is the after-sales service?

A: Our after-sales staff is online 24 hours a day, and the after-sales staff is received at any time, such as quality problems, we will replace unconditionally.