High Quality Drill Rod for Mining and Rock Drilling

Package size per unit product 100.00cm * 40.00cm * 40.00cm Gross weight per unit product 15.000kg Drifter rod, other nam

Basic Info

| Model NO. | T38/T45/T51/GT60 |

| Model Number | Extension Drill Rods |

| Machine Type | Drilling Tool |

| Processing Type | Forging |

| Use | Ore Mining, for Small Hole Drilling Tools |

| Body Length | 600mm-6400mm |

| Transport Package | Wood Package |

| Specification | SGS, CE |

| Trademark | PRODRILL |

| Origin | China |

| HS Code | 82071990 |

| Production Capacity | 10000PCS/Months |

Packaging & Delivery

Package size per unit product 100.00cm * 40.00cm * 40.00cm Gross weight per unit product 15.000kgProduct Description

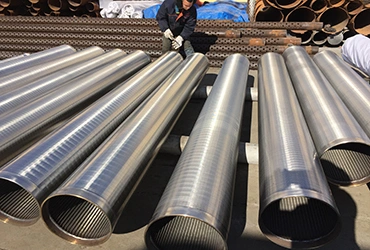

Drifter rod, other names are tunneling steels, tunneling rod, drifting drill rod, has round and hexagon shapes available, most of drifting drill steel with drill steel hexagon is for tunneling and drifting drilling application. Hexagon rods of rock drilling tools are more rigid, heavier and transfer energy more efficiently, while increasing flushing.Extension rod, other names are Extension drill steel, Extension drill rod, and Extension steel, M/F rod ( Speed rod ) , Produce Hexagonal and round cross sections, Hexagon rods are more rigid, heavier and transfer energy more efficiently, while increasing flushing. Round rods are generally lighter than hexagonal rods and are normally used in extension drilling applications. With the longer steel tending to be larger in diameter, conventional extension steel is characterized by a duplicate thread on each end of the steel.

For Extension Rod and M/F steel process, the below two different types of heat treatment are used to strengthen high speed and powerful percussive drill string components to maximize their performance and reliability.-Cannibalization is a process used to harden the entire rod surface both internally and externally to strengthen and extend the life of the rod. - High Frequency Induction is a process where only the thread ends of the rod are hardened to lengthen thread life.

Drifter rod, another names are tunneling steels, tunneling rod, drifting drill rod, has Round and hexagon rod available, most of drifting drill steel with drill Steel Hexagon is for tunneling and drifting drilling application. Hexagon rods are more rigid, heavier and transfer energy more efficiently,while increasing flushing.

It is common practice to bump up the drive end of drifting steel for added strength at the rock drill end to accommodate larger diameter and shank adapters. Drill steel is available in many standard lengths to match the drill feeds on a multitude of available drifting jumbos.Two different types of heat treatment are used to strengthen our percussive drill string components to maximize their performance and reliability. Cannibalization and middle frequency induction surface quenching as two process for strength the total quality and performance and life.

| Product Name: | Extension rod / Drift rod |

| Description: | Thread drill rod Made with best quality carbon steel bar, through heat treatment like famous brands |

| Material: | carbon steel bar |

| MOQ: | 5pcs |

| Body Type | Round shape and hexagonal type |

| Thread type | R25,R28,R32,R38,T38,T45,T51 |

| Diameter | Hex25,Hex28,Rd32,Rd38,Rd45,Rd51 |

| Type | Thread Extension Rod and MF rod |

| Length | 600mm-6400mm |

Advantages:

Compared with the oversea brands, our advantages are bellowing:

a. Our products can match over 95% against the original products

b. Price are competitive against the famous brands and best quality against the small factory

About Us:

1. Our factory has been specialized in manufacturing drilling tools and spare parts for over 15 years.

2. We have advanced technology and equipment.

3. Our technician has more than 15 year's professional working experience.

4. Rock drilling tools are exported throughout the world. Main market: Norway, Turkey, USA, Canada, Australia, Brazil, Uruguay, Philippines, Thailand, India, etc.

previous:

76mm DTH Drill Pipes/ Drill Rod

Send to us